What Is Supply Chain Management And Why Is It Important For Your Company?

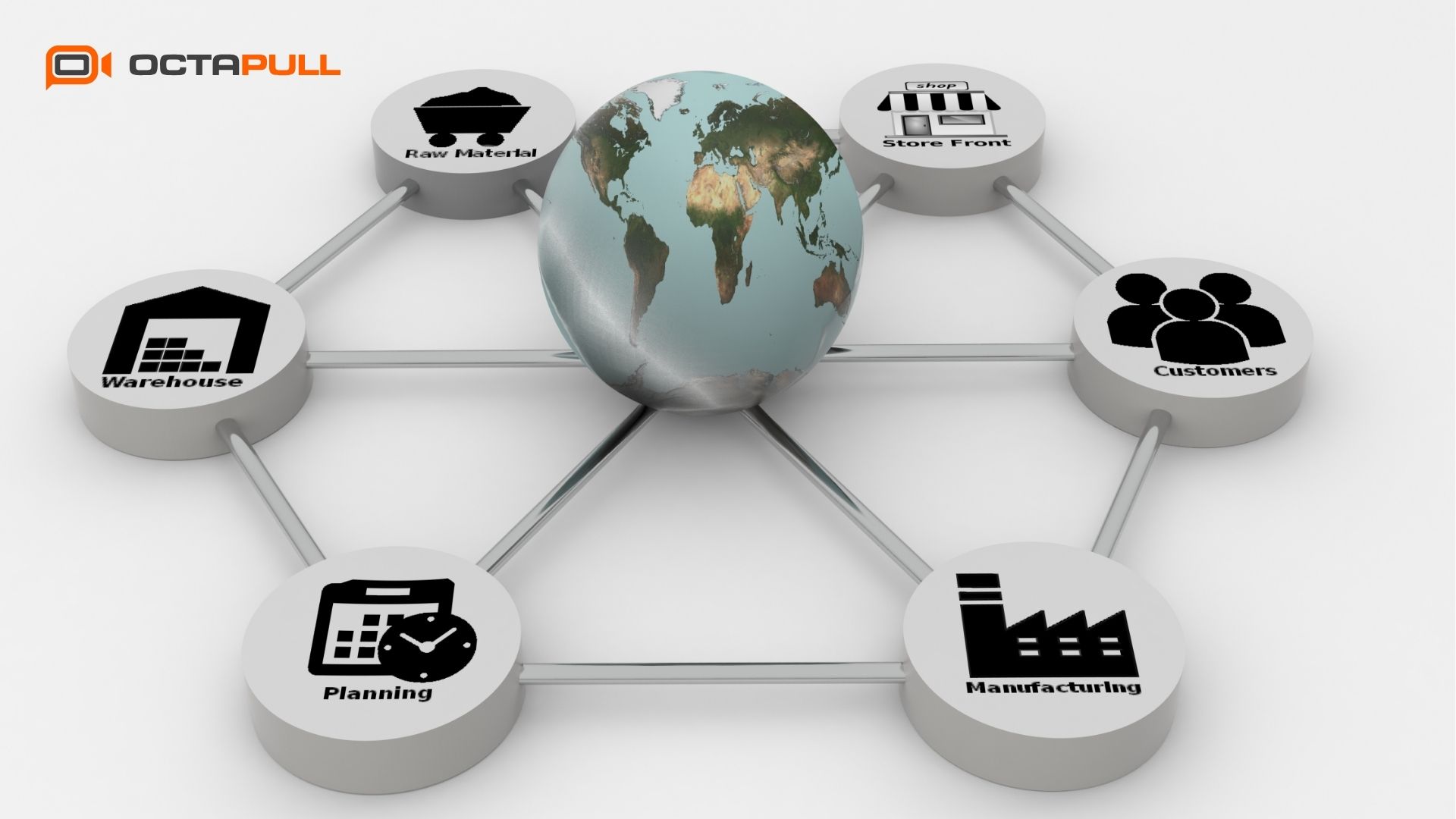

The supply chain is a network made up of suppliers, manufacturers, distributors, retailers, wholesalers, and customers.

Supply chain management is about effectively managing this vast network so everything goes smoothly in this cycle. From obtaining the commodity to producing and delivering it to customers.

What Is Supply Chain Management (SCM)?

Supply Chain Management (SCM) is the planning, organizing, and control of the flow of goods, information, and finance from suppliers to manufacturers, wholesalers, retailers, and finally to the end customer.

It’s about coordinating and integrating these flows within and between companies to meet customer demand.

Why Is Supply Chain Management Important?

Good supply chain management reduces costs, eliminates waste, and shortens lead times, which means big impact on profitability.

It gives businesses an edge in today’s global market. Research has shown that companies with advanced supply chain capabilities are 23% more profitable than their competitors.

Supply chain management also allows businesses to anticipate and mitigate risks such as supply chain disruptions while complying with regulations and industry standards.

By delivering products on time and in good condition, it increases customer satisfaction and loyalty.

With climate change in focus, sustainable supply chain practices are more important than ever. Businesses can reduce their carbon footprint and environmental impact by optimizing logistics, using energy efficiently, and reducing waste.

How Does Supply Chain Management Work?

Planning

The process starts with a strategy to balance supply and demand. This means forecasting customer demand, sales planning, managing inventory levels, and designing production schedules to meet that demand at minimum cost.

Sourcing

This stage is about selecting and managing suppliers who provide the raw materials or components for production. This includes negotiating contracts, and quality standards and maintaining good relationships with suppliers to get reliable resources.

Producing

In this stage, raw materials or components are turned into finished products. This means managing production lines, quality control, and optimizing processes to be efficient and cost-effective.

Delivering

Once products are ready they need to be delivered to customers or retailers. This means managing logistics such as warehousing, shipping, and distribution to get products to their destination on time and in good condition.

Returns

The final stage is about handling product returns, repairs, or recycling. This is important for customer satisfaction and sustainability as it ensures defective or unwanted products are managed and disposed of properly.

What Are The Types Of Supply Chain Models?

Supply chain management varies from company to company as every business has its own goals, challenges, and strengths. Here are some of the models businesses can use to manage their supply chain:

Continuous Flow Model

This is for businesses that produce the same product over and over and have consistent customer demand. It’s a traditional approach used in mature industries where demand doesn’t change much.

Agile Model

The agile model is about being flexible and adaptable. It’s for companies with unpredictable demand or those that make custom products and can adjust to changes in orders or market conditions.

Fast Model

This is for products with short life cycles, like fashion items. Companies using this approach produce and sell products before the trend goes out of fashion and maximize profits in a short window.

Flexible Model

The flexible model is for businesses with seasonal demand. It allows companies to increase production during peak periods and scale down during slow periods to be efficient throughout the year.

Efficient Model

For industries with thin margins this model is about cutting costs and being efficient. Businesses want to optimize equipment use, manage inventory, and streamline order processing to stay competitive.

Custom Model

When standard models don’t fit, businesses can create a custom supply chain to suit their needs. This is common in niche industries like automotive where technical requirements are more complex.

Simplify Supply Chain Management With OCTAPULL!

We’re making inventory management and other sales processes more streamlined and efficient with OCTAPULL’s next-gen digital solutions. With Octapull SFA (Sales Force Automation) any business can get AI-powered sales automation, advanced data reporting, and customer engagement tools all in one place.

Use OCTAPULL’s tools to give your customers a personalized experience and get your sales teams working in harmony with digital workflows.

Want to see Octapull SFA in action? Click here to book a demo today! You can use OctaMeet completely free for 30 days. Sign up today!